Preconstruction BIM/CAD Services for MEP systems

- MEP Engineering Calculations

- Value Engineering

- Production of Construction Document

- Constructability Review

Pre -Construction Process

For each project construction process MEP systems plays vital role and each project execution process involved three stages as follows .

Pre – Construction – In this process includes the feasibility study , designing , planning and cover up to the project BID/Tender Stage . In this stage basic involvement of Engineering firms or consultants .

Fig: MEP Project construction process Construction - This phase includes the co-ordination and production of shop drawing for installation of each accessories of MEP systems . In this stage basic involvement of GC , Sub- contractors .

Post – Construction- This phase includes the turnover of projects ( TOP ) of documents and drawings and involvement of facility management ( FM ).

MEP Systems

MEP system consists of basically three systems Mechanical, Plumbing and Electrical including the Fire Protection system. In building, MEP engineering systems plays the major role parallel with the architect, structure from conceptual planning, detail designing stage to execution stage. All individual systems have its own sub system as follows.

Mechanical System

Mechanical ducting : Mechanical ducting system consist of the mechanical equipment like AHU ,VAV ,CU , FCU ,RTU etc with duct , duct fitting , hangers ,dampers , access panel , access door etc. including all accessories.Mechanical piping: - Mechanical piping system consists of mechanical pumps, chiller, piping with fitting, valves, hanger and all accessories.

Mechanical Ventilation: - Mechanical ventilation system consists of exhaust, supply fan with duct, fitting and dampers, access panel, access door etc. including all accessories.

Plumbing System

Plumbing Drainage System: - Plumbing drainage system consists of piping with fitting, valves, hangers with all necessary accessories.Plumbing Water Supply system: - Plumbing water supply system consists of water pump, pipe with fittings, valves, hangers and necessary accessories.

Fire protection System

Fire Sprinkler System: - Fire sprinkler system consists of equipment like pump, sprinkler, test valve assembly, pipe with fitting, valve, and hangers with necessary accessories.Electrical System

Lighting System: - Lighting system consists of lighting panel, breaker, lighting conduit and lighting fixture, switches with necessary lighting accessories.Power System: - Power system consist of power panel, power cable, power conduit Junction Box, power socked, receptacle and necessary power accessories.

Fire Alarm: - Fire alarm system consists of fire alarm panel, conduit, cable, junction box fire alarm devices with necessary accessories.

Signal /ELV System (Telephone, Data, signal, CCTV):- All the signal, CCTV and ELV system consists with necessary panel with devices and network cables.

External MEP System: - External MEP plumbing system consists with underground plumbing & electrical system .External plumbing system consists with pipe with fittings, channel, Chambers, Catch basin and manhole.External Electrical system consist of substation, Generator, main LV panel, Cable tray, Underground conduit

Specialized plumbing System :- In plumbing system Irrigation , Gas , Medical Gas , WTP ( Water Treatment plant) , Sewage Treatment Plant ( STP ) , swimming pool systems considered as a specialized plumbing system .It consist with Pump ,valve and pipe with fitting and all accessories etc.

MEP Codes and Standards we follow

MEP system contract/design drawings in strict compliance with contract specifications, technical submittals and the relevant codes which we use internationally.

Mechanical Codes - ASHRAE, ASME, ASTM, SMACNA , AS1668.2 – 2012, AS 4254.2-2012Plumbing Codes- IPC , ASPE ,AS3500

Electrical Codes NFPA70 – NEC

Fire Protection NFPA -1, 13, 14

MEP Engineering Calculation

Thermal Lad calculation

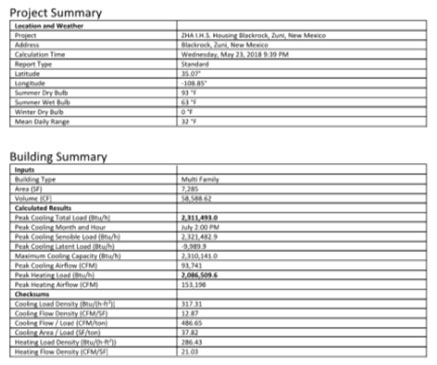

As per the international standard and guidelines ASHRAE, we do thermal load calculation through manually and through Autodesk Revit software which we use to provide for our US client.

Duct Sizing & Flow measurement

As per the ASHRAE standard, our engineering team calculate the duct size a per constant velocity method. Our team having the capability to evaluate the flow as per the project requirement. We also provide the proposed duct size as per the standard velocity method for any missing duct size of contract drawing.

Plumbing drainage and water pipe sizing

As per IPC fixture chart and inline with friction chart, we do the drainage fixture calculation, drainage pipe size and water supply pipe sizing.

Electrical Cable size and voltage drop Calculation

We do electrical cable size and voltage drop calculation as per the schematic inline with NEC .

Value Engineering

Virtual Construction of project in BIM enables Independent Review of the contract drawing in-line with requirement and technical specification we do internal value engineering with the following steps.

- Proposed re-rout with shortest distance for piping and ducting to reduce the material cost.

- Reduced the no of fitting and bends in the co-ordination.

- Optimization the design through constructability review.

- Reduce the duct size if require as per the specification and code.

Production of Construction documents

We produce permit Drawing/ Contract Drawing & design Models with the help of advance tools like Autodesk Revit in 3D and AutoCAD 2D process. 3D model creation process includes the following steps

- 1) Creation of template as per the design inputs

- 2) 3D models of equipment

- 3) 3D model MEP Piping all accessories

- 4) Our 3D MEP team has expert in all kind of building system starting from residential, commercial etc.

We use to get the markup from PE engineers /Consultants of mechanical, plumbing system on the architect layout. Based on the markups, our 3D team use to produce 3D permit drawing set. MEP Contract drawing /document set consist of following for each system .

- 1) General drawing& Notes

- 2) Floor plans

- 3) Schematics

- 4) Detail Drawing

Our team has been trained for production of mechanical, plumbing and electrical system contract drawing.

Constructability Review

The main purpose of the constructability review is to review all construction processes from start to finish during the pre-construction or at early design phase. This Constructability assessment helps to identify and solve different types of problems before the actual construction begins and helps to minimize errors, delays and overhead.Virtual Construction of project in BIM enables Independent Review of the Construction Plans and Specifications. This identifies discrepancies in drawings and all constructability issues at preconstruction stage. During the constructability review, our BIM team generates a series of RFI’s to identify following type of constructability and operational issues: